A deep dive into how replacing traditional harnesses with FPCs boosts performance and reliability in BMS.

In the evolving world of electronics, the need for compact, reliable, and error-free connections is greater than ever—especially in battery management systems (BMS), where precision and safety are non-negotiable. Flexible Printed Circuits (FPCs) from CEE PCB are increasingly becoming the go-to solution for BMS design, offering a streamlined alternative to traditional wiring harnesses and connectors.

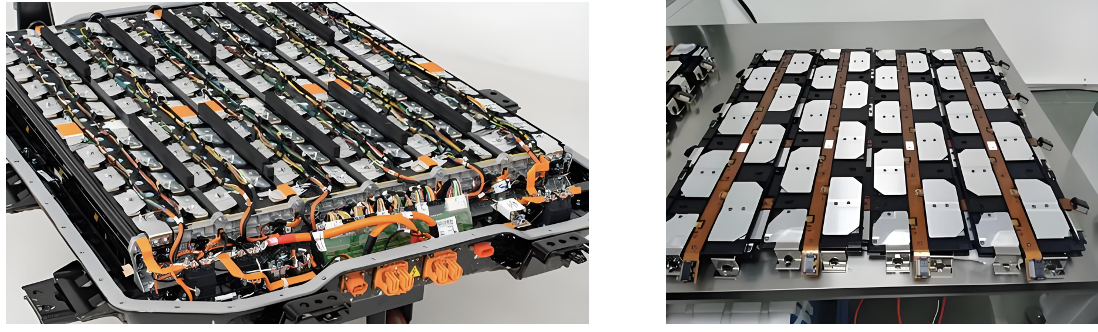

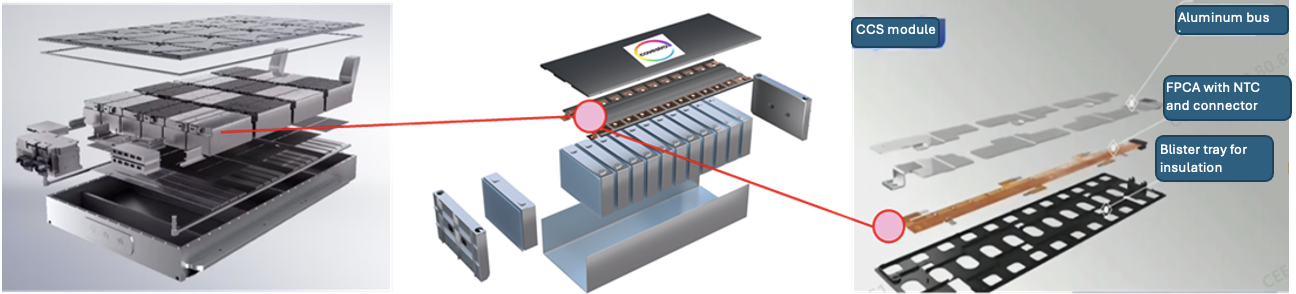

Left: Battery package with wiring harnesses and bulky connectors; Right: Battery cells connected by FPC with slimmed down design

Compact Design for Tight Spaces

One of the most immediate benefits of FPCs is their ultra-thin, lightweight construction. In battery management systems—whether in electric vehicles, portable devices, or energy storage units—space is at a premium. Traditional wiring can quickly become bulky and chaotic. FPCs, on the other hand, provide a neat, organized, and low-profile solution that can be folded, bent, and shaped to fit even the most constrained spaces. This allows engineers to design slimmer, more efficient battery packs without sacrificing performance or accessibility.

FPC used with less space required

Error Prevention and Connection Clarity

Miswiring is a common and costly issue in battery system assembly. A single incorrect connection can lead to failures, safety hazards, or long troubleshooting hours. FPCs significantly reduce the chance of such mistakes. Since they are manufactured as one continuous piece with pre-defined copper traces, the layout is locked in and repeatable. There’s no chance of switching wires or misaligning terminals during assembly. This built-in clarity not only improves reliability but also reduces training requirements and assembly time on production lines.

Improved Signal Integrity and Reduced Resistance

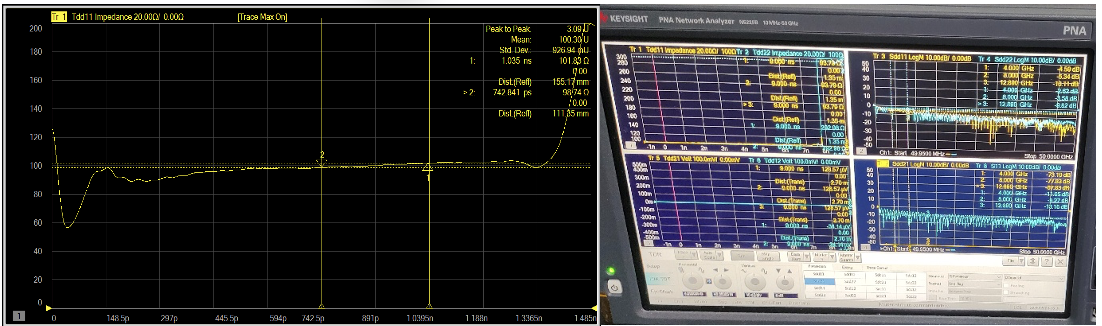

In high-performance battery systems—especially in electric vehicles and renewable energy applications—signal integrity and minimal resistance are crucial. FPCs provide consistent and controlled impedance paths for data and power signals. Unlike bundled wires, which can suffer from inconsistent routing and interference, FPCs deliver a stable electrical environment. The use of high-quality copper traces and precision manufacturing at CEE PCB ensures low resistance paths that contribute to better thermal management and system efficiency.

Left: Controlled impedance for FPC traces; Right: Insertion loss control for high speed FPC

Enhanced Safety and Durability

Battery systems operate under demanding conditions, including high temperatures, vibrations, and potential exposure to moisture or chemicals. FPCs from CEE PCB are designed to withstand such conditions. With robust insulation materials and tight layer bonding, they offer greater resistance to vibration and mechanical stress compared to individual wires. This improves the long-term durability of the BMS, reducing maintenance needs and extending product lifespan.

Streamlined Manufacturing and Cost Savings

By reducing the number of discrete wires, connectors, and manual assembly steps, FPCs simplify the manufacturing process. This not only speeds up production but also lowers labor costs and minimizes human error. CEE PCB supports custom FPC design, allowing clients to consolidate multiple functions into a single flexible circuit tailored to their specific application. Over time, this contributes to cost savings, improved scalability, and more consistent product quality.

The CEE PCB Advantage

With decades of expertise and a commitment to high-precision manufacturing, CEE PCB provides reliable, high-performance FPCs tailored for battery management applications. Their engineering team collaborates closely with clients to ensure each FPC design meets electrical, mechanical, and thermal requirements while staying within budget.

In conclusion, FPCs are transforming the way battery systems are built—making them smaller, smarter, and more dependable. For businesses and engineers looking to optimize their battery designs, CEE PCB’s FPC solutions offer a winning combination of simplicity, safety, and superior performance.